We are growing our dealer network. Apply today to become a dealer!

Top 10 Trailer Maintenance Tips To Extend Lifespan

A well-maintained trailer is key to ensuring safety, longevity, and cost-effectiveness. Regular trailer maintenance can prevent costly repairs and unexpected breakdowns, whether you use your trailer for transporting equipment, hauling heavy loads, or personal travel. Neglecting trailer maintenance can lead to issues like tire blowouts, brake failures, rust, and electrical malfunctions, compromising safety and leading to expensive replacements.

We’ve compiled ten essential trailer maintenance tips to help you keep your trailer in top shape. Follow these simple yet effective strategies to extend your trailer’s lifespan and keep it road-ready for years.

1. Regular Inspection

Routine inspections help identify issues before they become significant problems. A quick check before and after each use ensures your trailer remains in top condition. Look for signs of wear and tear, corrosion, loose connections, and any unusual noises.

What to Inspect:

- Tires – Check for wear, cracks, and proper inflation.

- Brakes – Ensure they are functioning correctly and not worn out.

- Lights & Wiring – Test all lights and look for frayed or loose wires.

- Hitch & Coupler – Verify the secure attachment and lubricate it as needed.

- Suspension – Look for worn-out or broken components.

A thorough inspection takes only a few minutes but can prevent expensive repairs and dangerous accidents.

How Often Should You Service Your Trailer?

The frequency of trailer maintenance depends on usage and load capacity. Here’s a general guideline:

- Before Each Trip: Quick safety check of tires, hitch, lights, and brakes.

- Every 3 Months or 3,000 Miles: Grease moving parts, check fluid levels, and inspect wiring.

- Every 6 Months or 6,000 Miles: Deep cleaning, check fasteners, inspect suspension, and test electrical connections.

- Annually: Full inspection, replacement of worn-out parts, repacking of wheel bearings, and addressing rust or frame damage.

Frequent inspections and servicing will keep your trailer road-ready for years.

2. Grease Moving Parts

Friction can cause excessive wear on your trailer’s moving components. Regularly greasing key areas reduces friction and prevents premature damage.

Where to Apply Grease:

- Wheel Bearings – Repack every 12 months or 10,000 miles.

- Hitch Coupler & Ball – Prevents rust and ensures smooth operation.

- Suspension Components – Reduces wear and extends lifespan.

- Jacks & Landing Gear – Keeps them moving smoothly without squeaking.

Use high-quality, waterproof grease for the best protection.

3. Monitor Fluid Levels

Fluids are critical in your trailer’s performance, especially if it has a braking system.

Fluids to Check:

- Brake Fluid: Ensure adequate levels and replace it if it looks dirty.

- Hydraulic Fluid: Check and top off fluid levels if your trailer has a hydraulic system.

- Grease & Lubricants: Reapply as needed to prevent wear.

Ignoring fluid levels can lead to brake failure and reduced performance.

4. Keep It Clean

Dirt, debris, and road salt can cause rust and deterioration. A clean trailer lasts longer and functions more efficiently.

Cleaning Tips:

- Wash your trailer regularly, especially after driving on salted roads.

- Use a pressure washer to remove mud, grime, and buildup from the undercarriage.

- Apply a rust inhibitor or protective coating on metal surfaces.

- Clean and dry electrical connections to prevent corrosion.

Keeping your trailer clean enhances both its appearance and durability.

- Check the Braking System

Your trailer’s brakes are important for safe towing. Worn-out or malfunctioning brakes can lead to dangerous situations.

Brake Maintenance Checklist:

- Test the brakes before every trip.

- Inspect brake pads and shoes for wear and replace if necessary.

- Check brake fluid levels and look for leaks.

- Ensure electric trailer brakes are functioning correctly.

If you notice unusual noises, a pulling sensation while braking, or poor stopping power, have your trailer’s brakes inspected immediately.

6. Examine Lights & Wiring

Wiring issues or faulty lights can lead to accidents and legal troubles. Ensure all electrical components are in good working order.

What to Check:

- Inspect wiring for frayed, loose, or corroded connections.

- Test brake lights, turn signals, and running lights before each trip.

- Replace burnt-out bulbs and broken light housings.

- Apply dielectric grease to wiring connections to prevent moisture damage.

Keeping the electrical system in top condition ensures visibility and road safety.

7. Maintain the Trailer Floor

A damaged floor can weaken your trailer’s structure and make it unsafe to transport heavy loads.

Floor Maintenance Tips:

- Inspect wooden trailer floors for signs of rot, warping, or cracks.

- Apply a water-resistant sealant to protect wood from moisture.

- Check for rust and treat metal floors with a protective coating.

- Ensure fasteners and bolts securing the floor are tight.

A well-maintained floor supports loads safely and extends the trailer’s lifespan.

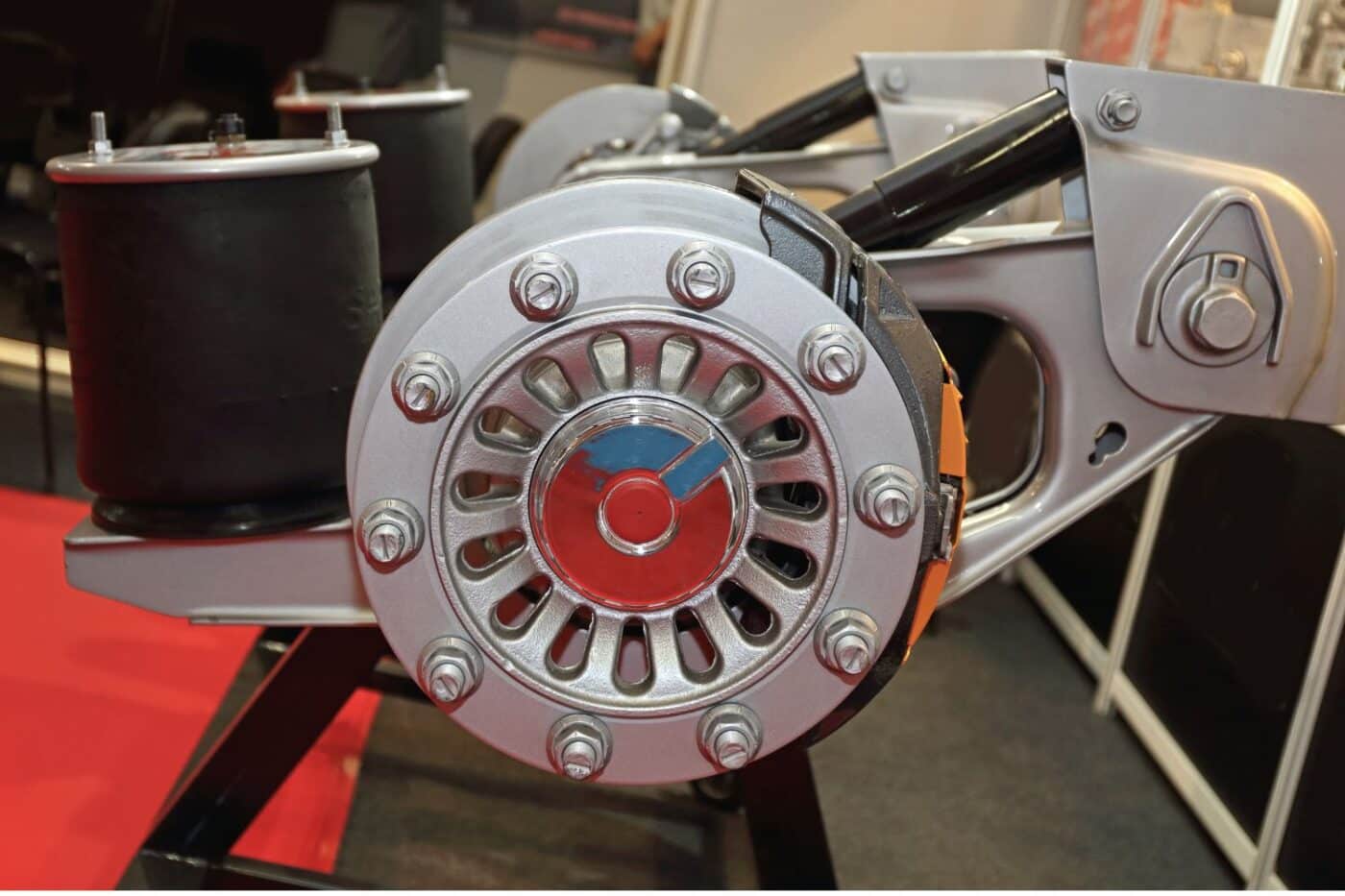

8. Inspect the Suspension System

A faulty suspension system affects ride quality and trailer stability. Regular inspections help prevent breakdowns.

Suspension Maintenance Checklist:

- Check leaf springs for cracks, sagging, or rust.

- Inspect shock absorbers for leaks or weak performance.

- Tighten U-bolts and suspension fasteners as needed.

- Replace worn-out bushings and mounts.

Ignoring suspension issues can lead to excessive tire wear and an uneven ride.

9. Secure Fasteners & Hardware

Vibrations from towing can loosen bolts, nuts, and other fasteners over time.

Fastener Maintenance Tips:

- Periodically tighten bolts and screws throughout the trailer

- Use thread-locking compound on critical fasteners.

- Replace missing or rusted nuts and bolts.

- Inspect tie-down points and D-rings to ensure cargo security.

Loose hardware can lead to structural instability, so regular checks are essential.

10. Store Properly

Proper storage prevents premature wear and protects your trailer from harsh weather conditions.

Storage Tips:

- Park in a covered area or use a waterproof trailer cover.

- Store on a level surface to prevent unnecessary strain.

- If storing for long periods, lift tires off the ground to prevent flat spots.

- Disconnect the battery if your trailer has one to prevent drainage.

Correct storage methods help extend the life of your trailer and reduce maintenance needs.

By following these trailer maintenance tips, you can enhance safety, prevent breakdowns, and maximize the lifespan of your trailer.

Trailer Maintenance for Specific Trailers

Whether you have a dump trailer, flat deck trailer, tilt deck trailer, car hauler trailer, tiny home trailer, or equipment trailer, regular upkeep can help prevent costly repairs and keep your trailer safe on the road.

Dump Trailer Maintenance

- Inspect the lift mechanism and grease pivot points.

- Check hydraulic systems regularly for leaks or wear.

- Ensure the dump bed is free of rust and debris for smooth operation.

Flat Deck & Tilt Deck Trailer Maintenance

- Inspect the deck boards for rot or cracks, especially if hauling heavy loads.

- Lubricate hinges and tilt mechanisms to ensure easy loading and unloading.

- Secure all tie-down points and check for wear.

Car Hauler Trailer Maintenance

- Ensure ramps and tie-downs are secure before transport.

- Check for tire pressure and tread wear, especially when hauling multiple vehicles.

- Inspect the trailer brakes and lights before each trip.

Tiny Home Trailer Maintenance

- Monitor frame integrity to support the home’s weight.

- Inspect axles and suspension to ensure a smooth ride.

- Regularly check wheel bearings and repack them as needed.

Equipment Trailer Maintenance

- Inspect ramps for weak spots or cracks before loading heavy machinery.

- Check suspension components for excessive wear from carrying heavy loads.

- Keep the braking system in optimal condition for added safety.

Regardless of the type of trailer you own, regular tire checks, brake inspections, lighting tests, and frame maintenance are essential. By following these maintenance tips, you’ll extend the lifespan of your trailer, improve safety, and ensure it performs reliably for years to come.

Arrow Trail | Premium Trailers

Arrow Trail is your go-to destination for high-quality, durable trailers designed to meet various hauling needs. Whether you’re transporting heavy equipment, construction materials, vehicles, or even building a tiny home, our trailers are built for strength, efficiency, and reliability. Our models are crafted to handle any job with features like hydraulic lift mechanisms for effortless unloading, open or tilt decks for easy access, and multiple tie-down points for secure transport. We also offer customizable powder-coating options to match your style or brand. With a network of dealers across the U.S., Arrow Trail ensures you get the right trailer delivered wherever you need it. Choose Arrow Trail for superior craftsmanship, exceptional service, and a trailer that works as hard as you do. Explore our extensive range of trailers and find the perfect fit for your requirements.